WHAT IS PROGRAMMABLE LOGIC CONTROLLER (PLC)?

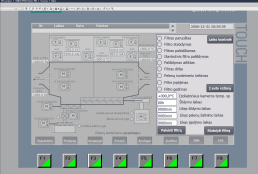

All In Container creates application software for PLC programming (Programmable Logic Controllers). PLCs are a critical component of industrial automation and control systems. It allows customers to design and implement control applications tailored to their specific needs. PLC in process control is as essential as having a personal work computer in the office.

All In Container‘s expertise in developing high-quality software for PLCs has made them a trusted partner for many companies in the process control industry. Our specialization: energy, food & feed production, and recipe-based (batch) manufacturing industries.

PLC programming is used in a wide range of industrial applications:

- Energy production and distribution

- Food and beverage processing

- Manufacturing and assembly lines

- Packaging and material handling systems

- Chemical processing and refining

PLC programming are responsible for monitoring and controlling various functions in real-time, meanwhile ensuring the production process runs smoothly and efficiently. Therefore, PLCs contain textual or graphical programming languages, allowing users to create custom logic for specific industrial applications. Particularly several programming languages can be used to program PLCs, including: Ladder Logic, Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), Sequential Function Chart (SFC).

WHY TO USE PLC PROGRAMMING IN INDUSTRIAL AUTOMATION?

- All In Container’s application software seamlessly integrates with PLCs, offering customers a user-friendly tool for programming their systems. The software is accessible to both experienced programmers and newcomers to industrial automation. With All In Container’s, customers can create customized logic for their PLCs without requiring extensive training or specialized knowledge.

- Furthermore, PLC programming is designed with a focus on performance. The software is optimized for real-time operation. So, it is ensuring that PLCs can promptly respond to changes in the production process. This responsiveness is particularly crucial in industries where even minor delays can impact productivity.

- Another notable advantage of All In Container’s software is its reliability. Testing is conducted to ensure flawless operation in the harshest industrial environments. This testing also helps identify and resolve potential issues before they can affect production, further reducing downtime and enhancing productivity.

In conclusion, All In Container’s PLC programming is a powerful tool for customers in the process control industry. Our specialization is energy, food, feed production, and recipe-based (batch) manufacturing. With its ease of use, flexibility, performance, and reliability, it’s no wonder that All In Container has become a trusted partner for many companies in this field. Whether you’re looking to create custom logic for a new system or optimize an existing one, All In Container can help you achieve your goals quickly and efficiently.