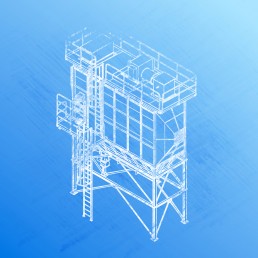

OPERATING PRINCIPLE OF AN ELECTROSTATIC PRECIPITATOR

Electrostatic precipitators are an efficient and effective way to control air pollution in various industrial applications. These devices use an induced electrostatic charge to remove solid particles from flue gas. Also, this solution provides high collection efficiency while consuming low energy levels. ESPs are particularly useful in biomass-fired plants, where they can remove high levels of particulate matter from the flue gas with low-pressure drops. In this text, we will tell you more about the operating principle of an electrostatic precipitator.

At All In Container, we specialise in developing advanced electrostatic precipitators for the energy and industrial sectors. Our ESPs are designed to comply with EU directives. Finally they ensure optimal performance and reliability with minimal maintenance requirements and low operating costs. We use high-quality materials and components to provide the best performance. What is more, we offer customised solutions for different applications and layouts.

OPERATING PRINCIPLE

- Electrostatic precipitator (ESP) involves several profiled collecting plate rows and discharge electrodes in the middle of these rows. Once gases pass through the ESP, solid particles gain a negative charge from the emitting electrodes. That happens as the electrons emitted from discharge electrodes accumulate on solid particles.

- The negatively charged particles then drift toward the positively charged collecting plates in the electric field. In sum, solid particles settle on positively charged collecting plates and form deposits. Occasionally, these plates are rapped, and dust particles fall to the bottom of the ESP. The solid particle collecting system removes these particles from the ESP. The flue gas distribution screens at the inlet and outlet provide the best cleaning performance by evenly distributing gas through the ESP cross-section.

- Furthermore, the most essential part of an ESP is the electrical field. The electrical field is generated using a high-voltage transformer rectifier. The electrical field is generated using a high-voltage transformer rectifier. At All In Container, we cooperate exclusively with the Swedish company KRAFT Powercon for transformers rectifiers.

Our team of experts works closely with clients to understand their specific needs and provide tailored solutions that meet their environmental goals. If you’re interested in learning more about our electrostatic precipitators and how they can benefit your business, don’t hesitate to get in touch with us today.